Exhibitor News

Pla Giken Co., Ltd. is to unveil their latest extrusion system, MIX-mini, which boasts a groundbreaking co-extrusion technology, Switch Mixing Mold. Switch Mixing Mold is designed to mix two resin materials, hard and soft, at a ratio changing during extrusion. This system was originally designed for medical catheter production to tailor the distal-to-proximal hardness transition for various clinical needs. However, this unique co-extrusion technology has the potential to serve other fields—such as automotive and electronics parts, robotics, etc.

In KOPLAS 2021, catheter shaft will be exhibited with this new extrusion system will be displayed, as well as an in-depth feature video which illustrates the advantages of Switch Mixing Mold.

Switch Mixing Mold is the second incarnation of Pla Giken’s catheter extrusion mold.

The idea for the first model was conceived in 1990s to overcome the shortcomings of traditional approaches in catheter production. Conventionally, the variable hardness of catheter shafts, from the hard proximal end to the soft distal tip, has been created by manually assembling discrete outer layer components, which are later thermally bonded together with a heat shrink tube. Not only is this process costly, the bonds between the components can be mechanical weak points and compromise the catheter shaft performance.

Pla Giken’s first solution to the above-mentioned issues, Switching Mold, made its debut in 1999. This extrusion mold connects multiple extruders and makes switches possible between different plastics during extrusion for continuous manufacturing of bond-free catheter shafts.

In 2018, the latest update to this line of catheter extrusion molds, Switch Mixing Mold, equipped on the catheter production system, MIX-mini, was released to further enhance the performance and reliability of catheter shafts by mixing two plastics inside the mold. The chief advantages of this technology are:

- Precision-controlled blending of two plastic materials creates a gradational transition (in hardness and other material properties) along the length of catheter shaft.

- By changing the parameter settings, this hardness transition can be tailored for various clinical purposes.

- Elimination of bonds leads to a greater shaft reliability and performance.

- With this approach, the production time of a catheter shaft can be reduced from hours (conventional approaches) to 5 mins (MIX-mini).

The core technology of Switch Mixing Mold is expected to find its applications in non-medical fields as well, such as automotive and electronics parts, robotics and any other industries where there are needs for “functionality graded” filaments, tubes, sheets, etc.

Pla Giken Co., Ltd. is an all-round manufacturer of plastic extrusion & processing systems, based in Osaka, Japan. In 2019, the president, Yoshiharu Kikuzawa, was awarded The Prime Minister’s Award (best award) at the eighth Monodsukuri Nippon Grand Award for the invention of MIX-mini.

▼ MIX-mini

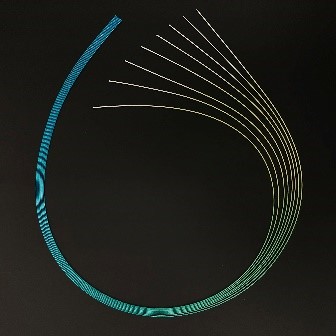

▼ Catheter Shaft Sample

- Previous Doil Ecotec exhibits Eco-friendly products !

- Next Hanam Trading Company, Korean Exclusive Agent for Labtech Engineering Co., Ltd, Leaders of Laboratory Sized Extruders and Other Machines: New 3 to 5 Layer Mini Blown Film Line, 3 Layer Cast and Calandaring Line, Two Roll Mill 6” with Built In Oil Unit